Buildtec Acoustics provides underlays with properties that address either airborne or impact noise. Airborne noise, such as music or conversations, can be reduced by selecting underlays with higher sound transmission class ratings. Adhesive or double-sided tape can be used to secure the underlay in place, while ensuring tight seams between pieces to prevent gaps that may reduce performance.

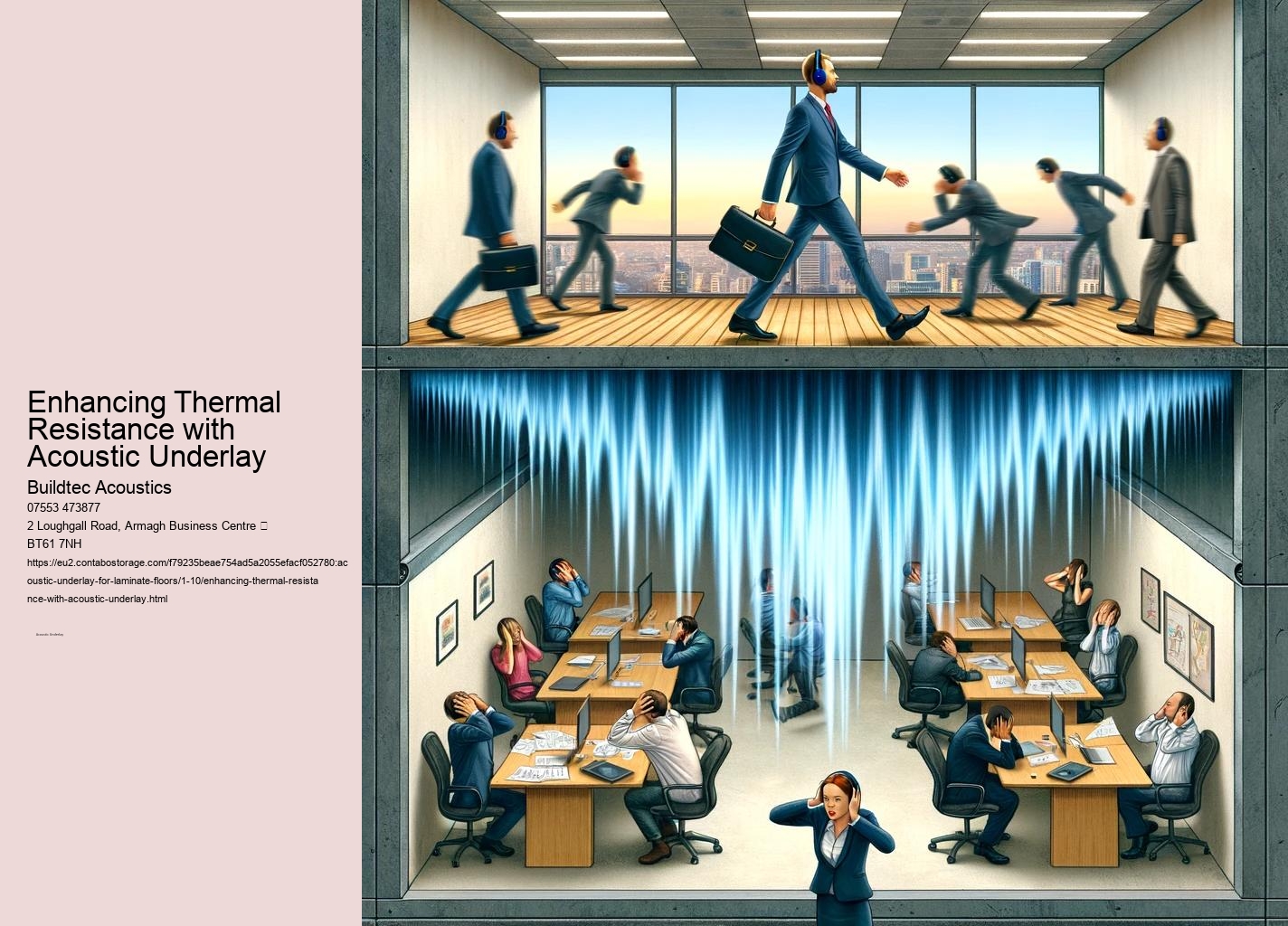

Lowering the sound transmission class (STC) and impact insulation class (IIC) ratings in a building helps create a more comfortable environment, especially in multi-story buildings where floors are connected through walls and joists, making noise control essential. Whether in a single-family detached home or a semi-detached house, installing acoustic underlay ensures that daily activities do not negatively affect others in the space.

Buildtec Acoustics offers a variety of acoustic underlays to meet different needs, including those designed for underfloor heating systems. Looking to dampen noise in your office then use acoustic underlay under your floor. Acoustic underlays are also effective for vibration isolation, particularly in areas with significant sources of vibration, such as near heating equipment or heavy appliances.

These options support sustainability by reducing reliance on virgin materials and lowering overall pollution. This contributes to better communication between occupants by reducing noise interference.

Adhesive or double-sided tape can be used to secure the underlay in place, ensuring tight seams between pieces to prevent gaps that could reduce performance. Acoustic underlays are also effective for vibration isolation, especially in areas where there are significant sources of vibration, such as near heating equipment or heavy appliances. This aspect is particularly important in multi-story buildings where different floors are connected through walls and joists, making noise control a priority.

This helps improve communication between occupants by reducing noise interference. Additionally, these materials offer excellent thermal insulation, which enhances the thermal resistance of a room while also managing noise levels.

The installation of acoustic underlays is straightforward and suitable for both professionals and do-it-yourself (DIY) enthusiasts. In residential buildings, whether in a semi-detached house or an apartment, acoustic underlays are often installed under laminate flooring, hardwood, or carpets to reduce noise transmission through walls, ceilings, and stairs.

Acoustic underlays are also effective for vibration isolation, particularly in areas with significant sources of vibration, such as near heating equipment or heavy appliances. Hard surfaces, such as hardwood and laminate, often amplify sounds like footsteps, leading to unwanted echo and reverberation.

Providing further details on the benefits of acoustic underlays.

Posted by Francis Mckenna on

Acoustic underlay is a critical solution for effective noise control in residential and commercial environments. Adhesive or double-sided tape can be used to secure the underlay in place, ensuring tight seams between pieces to prevent gaps that could reduce performance. These underlays not only help with noise reduction but also improve thermal conductivity, promoting efficient heat transfer within the room.

The installation of acoustic underlays is straightforward and suitable for both professionals and do-it-yourself (DIY) enthusiasts. Acoustic underlays do not compromise the aesthetics or design of the finished floor.

Buildtec Acoustics provides a comprehensive range of acoustic underlays designed to address both airborne and impact noise, making them suitable for various flooring applications, such as wood flooring, ceramic tiles, and laminate flooring. The underlays act as a cushion that helps to minimize the transmission of vibrations and sound through the floor. In residential buildings, whether in a semi-detached house or an apartment, acoustic underlays are often used under laminate flooring, hardwood, or carpets to reduce the noise that can travel through the walls, ceiling, and stairs.

Some underlays are certified by Leadership in Energy and Environmental Design (LEED) standards, supporting sustainable building practices. For example, underlays installed beneath medium-density fibreboard (MDF) or gypsum drywall help absorb vibrations and reduce unwanted sound transmission.

Before installing an acoustic underlay, it is important to ensure that the subfloor-whether concrete, particle board, or cement-is clean, level, and dry. Before installing an acoustic underlay, it is important to ensure that the subfloor-whether concrete, particle board, or cement-is clean, level, and dry.

In commercial settings, reducing noise pollution creates a more productive and pleasant work environment, enhancing overall efficiency. Acoustic underlays are compatible with a wide range of flooring materials, including tiles, carpet, and wood.

Acoustic underlays are compatible with various flooring materials, including tiles, carpet, and wood. Acoustic underlay is a fundamental solution for effective noise control in both residential and commercial spaces. Including acoustic underlays in renovation projects also helps ensure compliance with building insulation standards and soundproofing regulations, providing peace of mind to homeowners and builders.

Whether in a single-family detached home or a semi-detached house, the installation of acoustic underlay ensures that daily activities do not negatively affect others. Most underlays come in sheets or rolls and can be cut to size with simple tools like a utility knife.

The installation of acoustic underlays is straightforward and can be carried out by both professionals and do-it-yourself (DIY) enthusiasts. In conclusion, acoustic underlays from Buildtec Acoustics provide an effective solution for soundproofing floors, improving room acoustics, and enhancing overall comfort.

During renovations, installing acoustic underlays can significantly enhance the acoustic properties of existing floors, whether in residential or commercial settings. Acoustic underlays function by absorbing and dissipating sound energy, which helps to minimize noise transmission through floors.

Installing acoustic underlay beneath wood or laminate flooring can significantly reduce noise levels in rooms. Acoustic underlays made from polyvinyl chloride (PVC) or cork are ideal choices, as they balance both thermal insulation and soundproofing requirements. In addition to their sustainability, these materials are low in volatile organic compound (VOC) emissions, ensuring a healthier indoor environment.

The compatibility with different floor finishes makes acoustic underlays an essential component of modern flooring design, helping to create a space that is both visually appealing and acoustically comfortable. For example, underlays installed beneath medium-density fibreboard (MDF) or gypsum drywall help absorb vibrations and reduce unwanted sound transmission.

These products provide greater efficiency in both heating and noise control, offering comfort throughout the year. The primary function of acoustic underlays is to address both impact noise and airborne sound.

These products ensure enhanced efficiency in both heating and noise control, providing comfort throughout the year. In commercial settings, reducing noise pollution creates a more productive and pleasant work environment, enhancing overall efficiency.

Acoustic underlay installed beneath wood or laminate flooring can significantly reduce noise levels in rooms. The materials used in acoustic underlays, such as foam, cork, and natural rubber, are highly effective at reducing vibrations and controlling noise. Acoustic underlays do not compromise the aesthetics or design of the finished floor.

Acoustic underlays made from polyvinyl chloride (PVC) or cork are ideal choices, as they balance both thermal insulation and soundproofing requirements. Acoustic underlays made from polyvinyl chloride (PVC) or cork are ideal choices, as they balance both thermal insulation and soundproofing requirements.

Additionally, these materials are low in volatile organic compound (VOC) emissions, contributing to a healthier indoor environment.

Acoustic underlay can be installed beneath most types of flooring, including laminate, wood, and tiles. The subfloor should be clean, level, and dry before installation. The underlay is typically rolled out and cut to size, with seams tightly butted together. It can be secured with adhesive or double-sided tape if needed.

Acoustic underlays are an excellent choice for renovation projects as they can easily be installed under new flooring to improve noise insulation. They help bring older buildings up to modern soundproofing standards, making them more comfortable for occupants.